Today we’d like to introduce you to Aaron Johnson.

Alright, so thank you so much for sharing your story and insight with our readers. To kick things off, can you tell us a bit about how you got started?

Clear Cut Woodworking started out in late 2020. I had a love for woodworking and entrepreneurship, and I had built numerous pieces of furniture and items throughout the years, such as a cedar strip canoe, coffee table, medicine cabinet, etc. These projects fueled my passion for woodworking, and my passion continued to increase throughout the years. However, with as saturated of a market as custom-made furniture seems to be, I was apprehensive to dive into opening a business framed around a furniture maker model.

Also, unfortunately, I was temporarily in a living situation where I was limited in space for all my woodworking tools. So my train of thought shifted from running a regular woodworking business to purchasing a laser in which I could do some woodworking-related things, but not need an entire woodshop to do so. In October 2020 I purchased a laser engraver to use as my primary “tool,” initially planning on using it to create Christmas ornaments, plaques, custom engraved cutting boards, cribbage boards, etc.

A few days after owning the laser, I was tinkering around with it, testing out different files, and simply learning how it worked. By random chance, I uploaded an aviation-related document into the software and fired up the laser to see what would result.

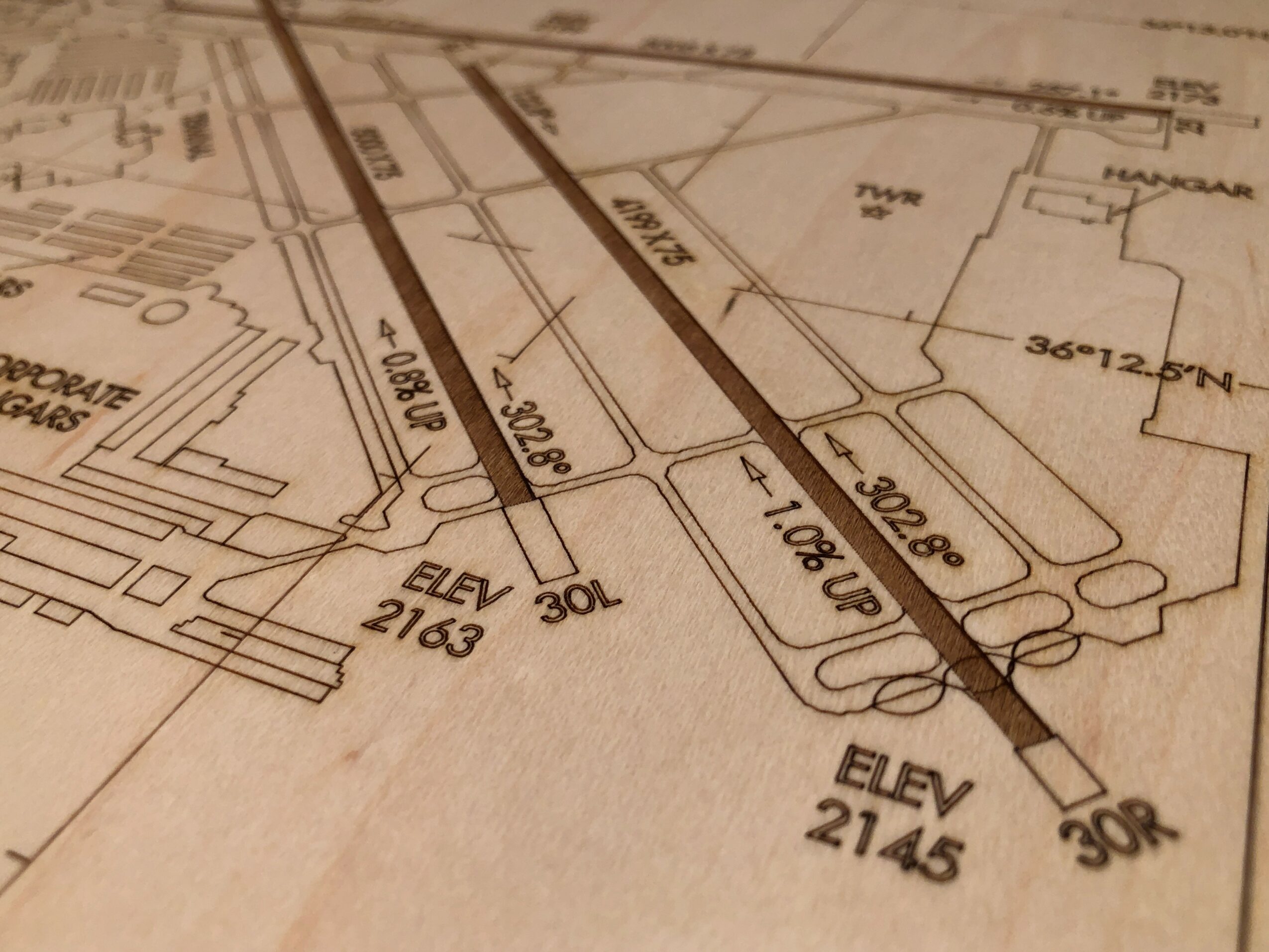

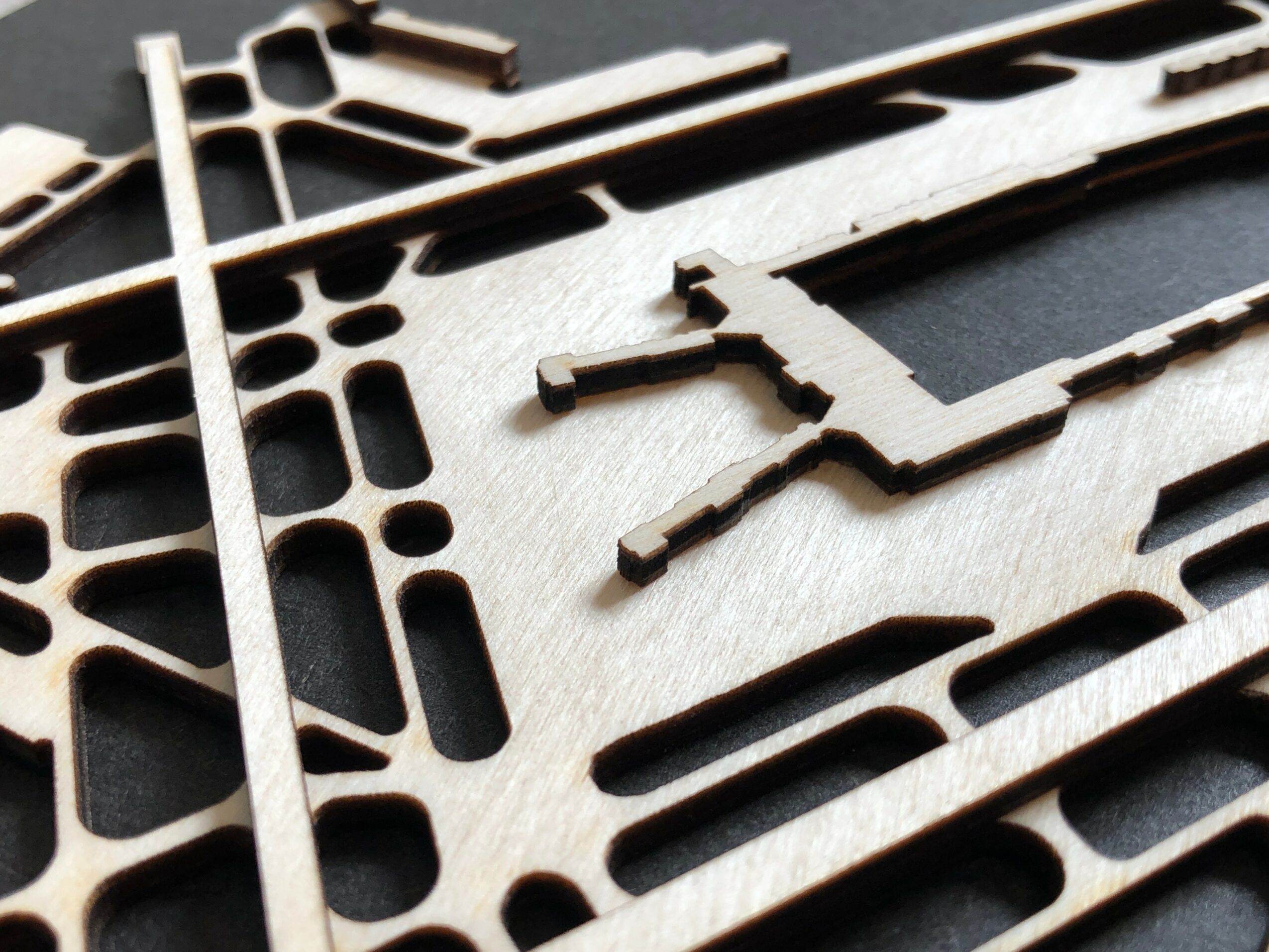

What resulted was an intricately detailed airport diagram, not perfect by any means, but a prototype of something great. Right then I knew I was onto something and I immediately started working on perfecting the laser file. Edits were made to correctly shade the runways, engrave letters, and scale the file to size, and adjustments were made to the laser power, cutting speed, focal distance, etc. I also researched and experimented with what kind of products I could laser these diagrams onto. Coasters, wooden frames, plaques, etc. were quickly developed. It wasn’t long and I was able to come up with airport diagrams ready to laser onto essentially any wood surface.

I made a few social media posts to see if there was any interest. Within hours my inbox was flooded with inquiries, people from all over asking me to make their airports from all across the U.S. I quickly went to work editing files for the newly requested airports, cutting out coaster blanks, and building wooden frames. Although I did not have my full woodshop, I did have access to a few basic tools such as a miter saw and table saw which was just enough to supplement this type of product. This “rush” of orders continued all the way through the 2020 Christmas season, and I was staying busy enough that I knew a simple email and Venmo/PayPal account wasn’t going to support this much longer.

My wife stepped in and helped me create a website, to help funnel all orders and requests through one centralized place. An LLC was opened, new products were developed and posted on the website, and so forth. With the help of several others, I was able to get a custom logo, social media presence, and so forth. The interest continued to grow, and I have now sent out orders to 36 different states (one goal is to have a customer in all 50!) in the business’s short life. The business has now connected and works with marketing managers, business professionals, and event organizers to create client gifts, retirement plaques, rewards, etc.

Would you say it’s been a smooth road, and if not what are some of the biggest challenges you’ve faced along the way?

One of the biggest obstacles in the early days was the living situation I was in. I was temporarily living about 45 minutes from where I stored the laser, due to room constraints. With how busy the business was, I spent a lot of time on the road between the laser and where I was living.

Lately, the biggest struggle has been the production side of things. I still have a full-time job and have 3 kids ages 5 and under.

With as busy personal life as I have ever had, it’s been tough to have time to not only fulfill orders but to develop and produce new products, which is something I want to do.

Is there anything else you’d like to share with our readers?

Clear Cut Woodworking is always looking to partner up with other woodworking or aviation enthusiasts to help create more products and niche-related items that will improve the customer experience.

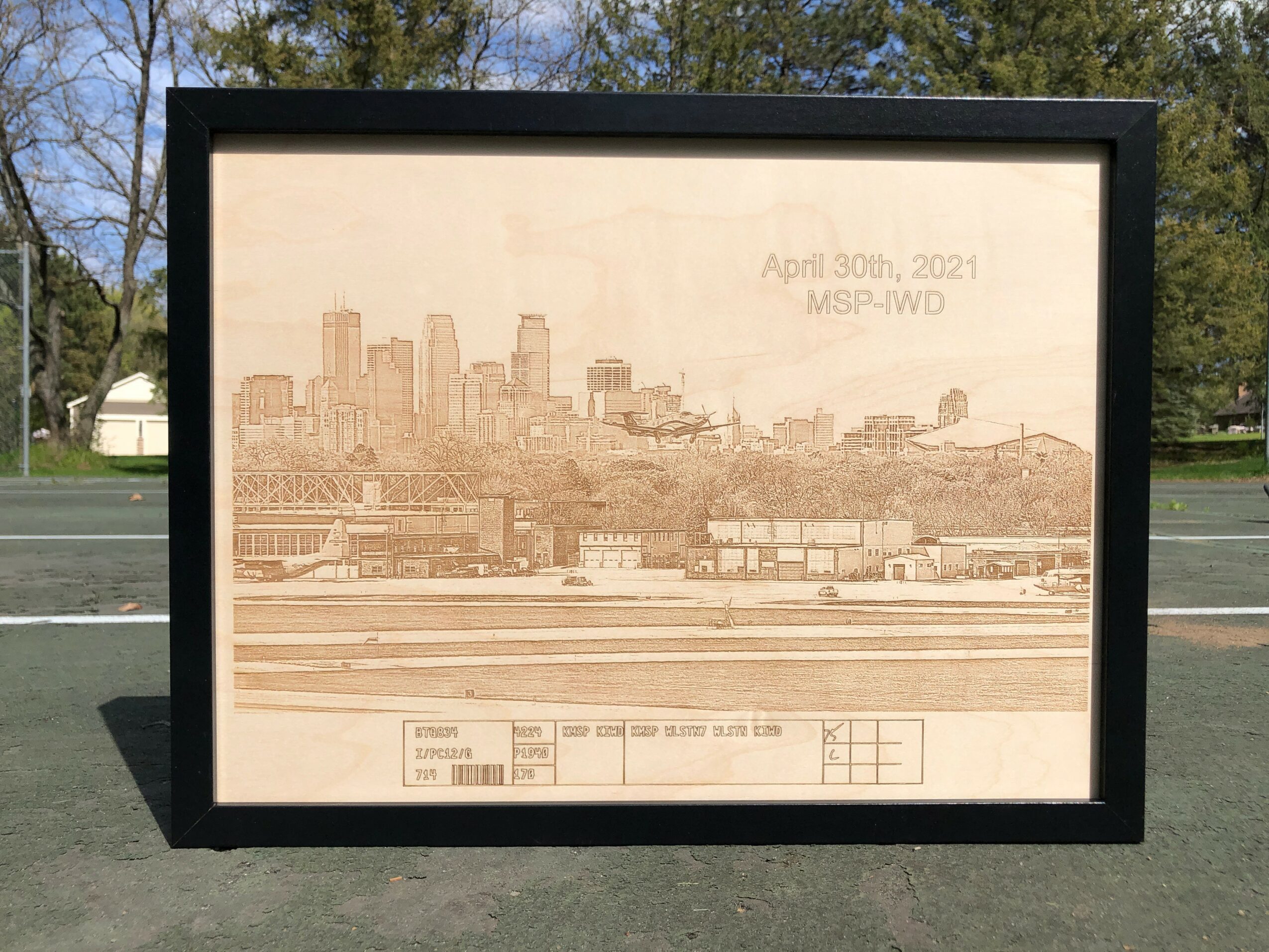

Clear Cut Woodworking also loves to see customers’ requests become reality, our favorite projects are ones with a personalized touch, such as custom text, their own laser engraved photo, etc.

Pricing:

- Coasters $35+

- Airport Diagrams $35+

- Laser Engraved Photos $35+

- 3D Airports $199

Contact Info:

- Email: [email protected]

- Website: www.clearcutwoodworking.com

- Instagram: https://www.instagram.com/clearcutwoodworking/

- Facebook: https://www.facebook.com/clearcutwoodworking

- Twitter: https://twitter.com/ClearcutW

- Youtube: https://www.youtube.com/channel/UCKS7tSJ6Ri3cko1UlCboQNQ