Today we’d like to introduce you to Todd Frederick.

Hi Todd, can you start by introducing yourself? We’d love to learn more about how you got to where you are today?

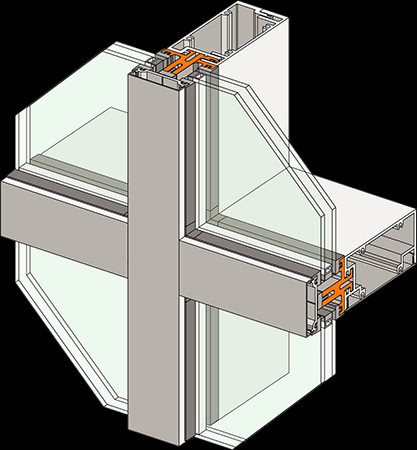

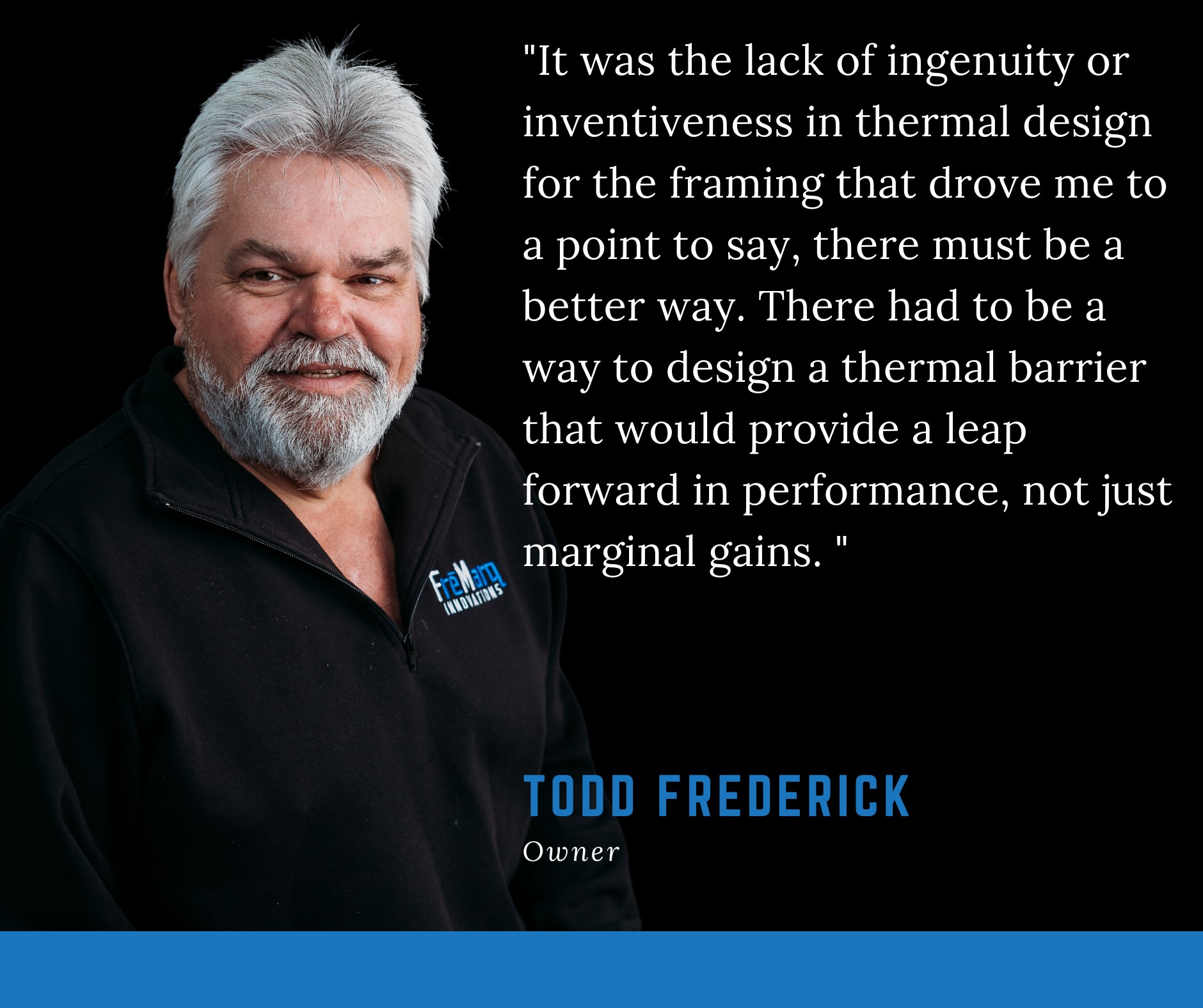

I started in the curtain wall/window industry in 1982 working for a major manufacturer as a designer. I moved up to engineering manager overseeing a group of designers. During my time there I was responsible for custom product designs, project scheduling, project mock-ups and customer service. In 1996, I left that company to work from home providing design services to a number of clients across the country. Shortly after that, I was contacted by a client that needed some custom fabrication done and that is how I got started with fabricating. By 2000 I had a team of 10 people and 20,000 square feet of building. By 2004 we had grown to 30 people and 160,000 square feet of space. We had a full-service engineering department and manufactured curtain wall, both stick and unitized, along with doors, storefront, and sunshades. In 2009 we sold the company and in 2014 I started to design a curtain wall system that would provide thermal performance that is 25% better than any other product on the market and I would do this by focusing on the frame design. After 2 years of R & D, I had developed a frame that provided assembled U values that were as much as 40% better than any other product on the market and at a competitive cost. We created FreMarq in 2016 and today have 40 employees and are located in our original 160,000-square-foot building. We offer a full line of high-performance products that include unitized curtain wall, stick curtain wall, fixed windows, and operable vents, all with our patented FortMax Thermal barrier.

Alright, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

It has not been a smooth road. When we started FreMarq in 2016, the world had changed a lot since 2009. Although we had a great track record with our first company, we found financing to be a real problem. To start a manufacturing company takes capital and banks today are not going to help a start-up, even though we had orders. We were fortunate to find some private investors that understood what we had and provided us with a foundation to start with. We have also struggled with the same issues all businesses have, the pandemic, shortage of qualified workers and inflation. However, the future looks great. We are finishing 2022 strong and have a great 2023 to look forward to.

Thanks – so what else should our readers know about your work and what you’re currently focused on?

Although I own the company, my passion has always been design, both project and product. I like taking a complicated project and uncomplicating it as much as possible without losing the desired appearance the designer is looking for. This helps to minimize the manufacturing and installation of the finished product. I have been known to make what looks to be impossible, possible. But what I am most proud of, and known for, is when I commit to making something happen, whether it’s a design or a delivery, I will do whatever it takes to meet that commitment. I can’t tell you how many times I have spent all night on the drawing board to meet a date or sent some of my guys, who volunteered, in a U-Haul across the country with frames to help a customer meet their commitment. Sometimes it costs us money to do the right thing, but our customers appreciate the effort.

Are there any important lessons you’ve learned that you can share with us?

The most important lesson I have learned over the past 40 years is that no matter how much you know, you don’t have all the answers and you need a great team around you to be successful. I have been very fortunate to have my wife Renea as a partner in the business. She takes care of so many of the important things that keep us going, like payroll, taxes, employee benefits and so much more, and she did all of this without having a support staff of her own. I have also been fortunate to have Renea’s brother Dale as a partner. He has managed our production area and has been the person I can rely on to help us meet those commitments I make. Having this three-legged stool, me with the ideas, Dale fabricating them and Renea keeping us both in line, has been a blessing and is something every business needs.

Contact Info:

- Website: https://fremarqinnovations.com/

- Instagram: https://www.instagram.com/fremarqinnovations/

- Facebook: https://www.facebook.com/FreMarqInnovations

- Twitter: https://twitter.com/fremarq