Today we’d like to introduce you to Rob And Rachel Prekker.

Rob and Rachel, we appreciate you taking the time to share your story with us today. Where does your story begin?

We are a small family-owned Gourmet Mushroom farm located in Pine River, Minnesota and have been growing for about 6 years. When Rob and I met he hated his job and had run successful home businesses in the past, so we started brainstorming something he could do from home and one night I made a half joking comment about growing mushrooms! Rob started researching as we had zero knowledge of growing mushrooms, and after a few months we jumped in head-first and had no idea how interesting things would get! Both Rob and I worked day jobs, so in our first few months we would stay up late at night (taking turns napping) cooking substrate blocks 3 at a time in pressure cookers on the kitchen stove top until we had enough to inoculate. We slept little and worked hard, after a few months we were growing our first strain of mushroom and knew we had a unique idea for our area. Fast forward through our first official business-to-business sale and a blur of leaps and bounds, we ended up moving in June of 2019 to a home we could use to expand the business.

In 2021 we made a huge leap into purchasing an 8,800 sq. ft. warehouse in Pine River and have re-constructed the whole business by ourselves making everything 4 times larger. Our laboratory is a complete positive pressure laboratory with a 6-foot self-fabricated Hepa-filtered flow hood, we fabricated our own steam sterilization barrels to cook over 180 blocks a week, and with our increase in only 1 grow room we can produce thousands of pounds of delicious gourmet mushrooms each month. I cannot put into words, nor emphasize how much work and passion we have put into growing quality mushrooms.

Our farm does everything from the base up, so we know what we put into our product. The process begins by us mixing and steam sterilizing our own substrate blocks, then inoculating the blocks in our laboratory, storing blocks for colonization, and finally- fruiting the mushrooms in one of our two indoor fruiting rooms. The best part is since our operation is indoors and the fruiting rooms are completely environmentally controlled- we can grow all year long!! We do not use any chemicals on our mushrooms, in the spawn, or production blocks. We spend hours each week cleaning the two grow rooms- including the humidification system, grow racks, walls, scrubbing the floors and cleaning up the grow blocks. Currently, we have over multiple strains in continuous production including Oyster mushrooms (Blue, Black, Italian, Kings), Lions Mane, Chestnuts, Nameko, Shiitake, Brown Beech and Hen of the Woods. We offer our fresh produce in bulk, or in ¼ pound PLA plastic compostable containers that we label with the strain and hints for cooking. In 2022 we added dehydrated functional mushroom options such as Turkey Tail, Reishi, and Cordyceps, as well as adding gourmet dehydrated in whole and powder form for cooking.

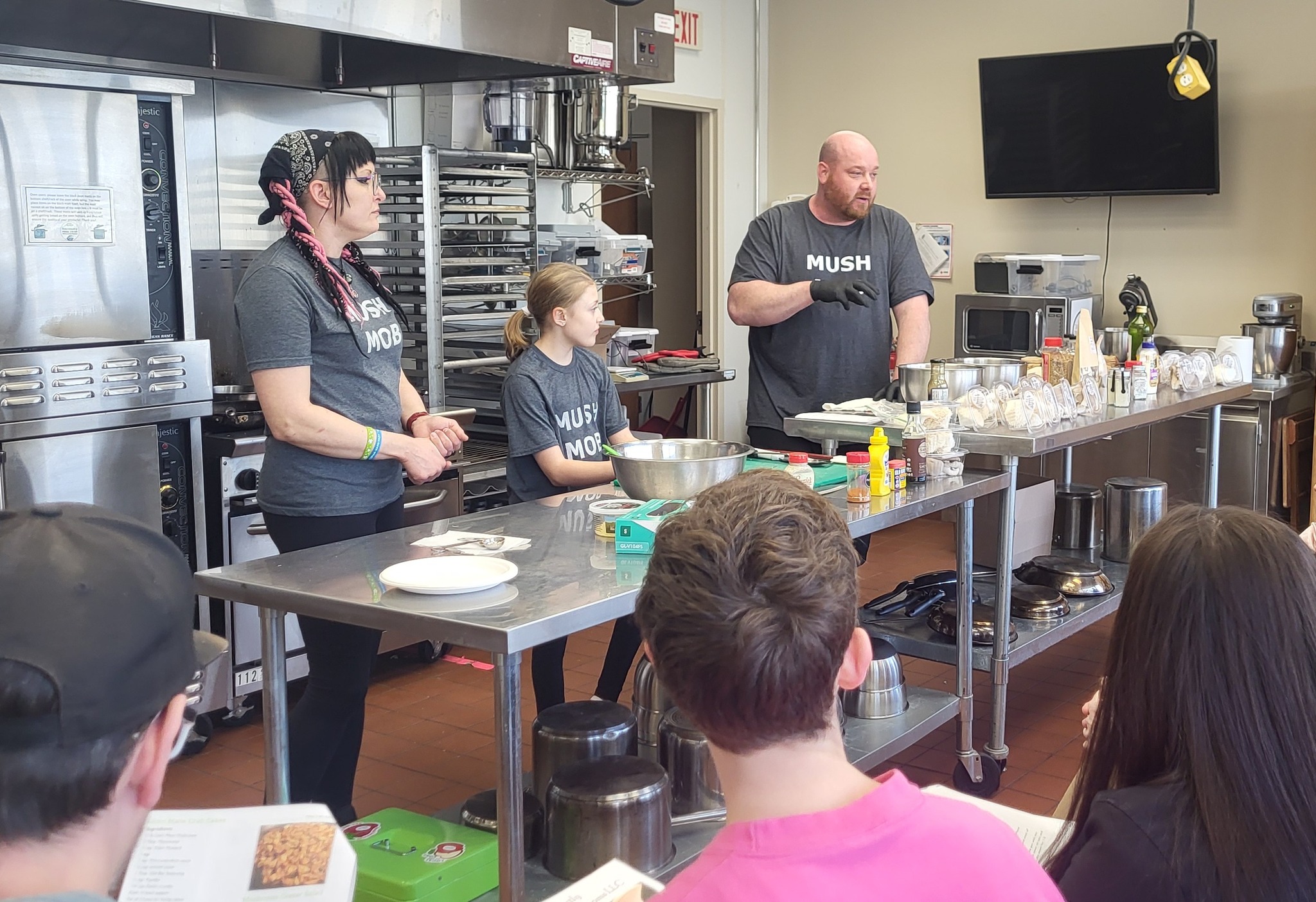

Now in 2025 with one full time adult, one part time adult, and one ten year old, we continuously supply coops and restaurants from Grand Marais, MN all the way to Northfield and into Wisconsin – as well as farmers markets, special events, and donating to fundraisers to support our local community. We are very thankful for the communities and individuals that have supported us and will always remember where we started.

#mushlove from the “Mush Mob,”

Rob, Rachel, and Selah

Strictly Mushrooms LLC

“You haven’t had a mushroom until you’ve had Strictly Mushrooms!”

Find us on Instagram, and check us out on Facebook @ Strictly Mushrooms

Alright, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

I think most entrepreneurs would agree that starting your own business from scratch is never a smooth road… mushroom farming is quite unique and is what I like to call “scientific gardening.” One of the largest struggles faced has to do with the equipment needed to produce mushrooms on a larger scale. For example, we have the capability to sterilize 150 grow blocks at one time- to buy an autoclave that size has an astronomical expense, so we had to figure out how to build equipment to do the same job but for a much cheaper price, and we are completely self-funded. There is a LOT of research, trial, and error….. We have not quit growing since we started in 2019 and have moved the mushroom farm 2 times. This last move we increased the size of everything to 4 times of what we had currently by purchasing a 8,800sq. ft. warehouse and did a complete re-build of everything including 2 -14×20 environmentally controlled fruiting rooms, a 12×24 positive pressure laboratory with a 6 foot flow hood, multiple steam sterilizers, over a dozen colonization racks that are 8ft long, 3.5ft wide and over 8ft. tall, along with all the electronics and equipment fabricated to run the farm which entailed over 17 hours days with 2.5 people…. There are so may technicalities with growing mushrooms I could write a whole paper on things not going smoothly lol

As you know, we’re big fans of you and your work. For our readers who might not be as familiar what can you tell them about what you do?

Well, we grow mushrooms lol! One thing we have found is that when customers visit the farm it is completely different than what they expect. Most people think of mushroom farming as trays and trays of compost with button mushrooms growing in the dark, and when they walk in all they can see is racks of colonizing mushroom blocks. Our mushrooms grow on a wood base with some nutritional supplementation; we basically make a fake log in a bag and then get sterilized. After cooling, the blocks go into our lab and get inoculated with spawn in front of our flow hood, sealed shut with an impulse sealer, mixed, and then they rest on our colonization racks until they are fully colonized and ready to be fruited. Each strain of mushroom is different in colonization time and varies anywhere from 7 days to 3 months before we can fruit them; for example our most aggressive strain is Italian Oysters, they only take 7-10 days to colonize and then 7-10 days before harvesting; Shiitakes take 2-3 months to colonize and then 10-14 days before harvesting; and Lions Mane takes 10 days to colonize but 21 days before harvest. Each strain has a specific way it likes to be fruited and vary in preference for humidity, temperature, lighting, and how to get them to grow. There is a lot of trial and error, and even though our grow rooms are controlled there are micro-climates in them, so sometimes I have to move mushrooms to different areas of the room to get them to fruit at their best. We definitely pride ourselves in the quality of our mushrooms, we have the capability to produce thousands of pounds but the quality drops when you fruit them in higher temperatures, we choose to keep our rooms cooler to produce beautiful hearty mushrooms, and we harvest twice a day to make sure they are picked at the best time! We spend a lot of time with our fruiting rooms, they are deep cleaned weekly and meticulously monitored; not to mention going through hundreds of grow blocks- I have a strain that has a 2-day window to take the next fruiting step or it will not grow properly. It’s like having a bunch of picky children lol. We also only package mushrooms that are 2-3 days from harvest

(at the most) before directly sending to our customers because we want them to be as fresh as possible. We have literally put blood, sweat, and tears into our farm and we continually strive to be better- we are set apart from others- not for what we do- but as I mentioned before- it is because everyone who has supported us along our journey! #mushlove!!!

We all have a different way of looking at and defining success. How do you define success?

To succeed you need to be able to take your failures as a learning opportunity and not quit, no matter how hard it gets.

Contact Info: